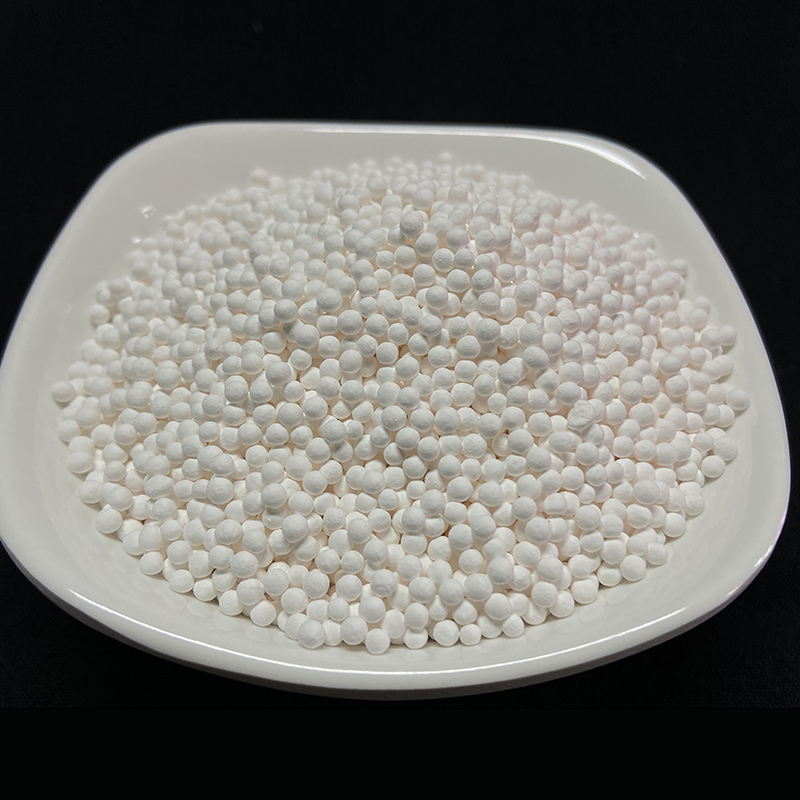

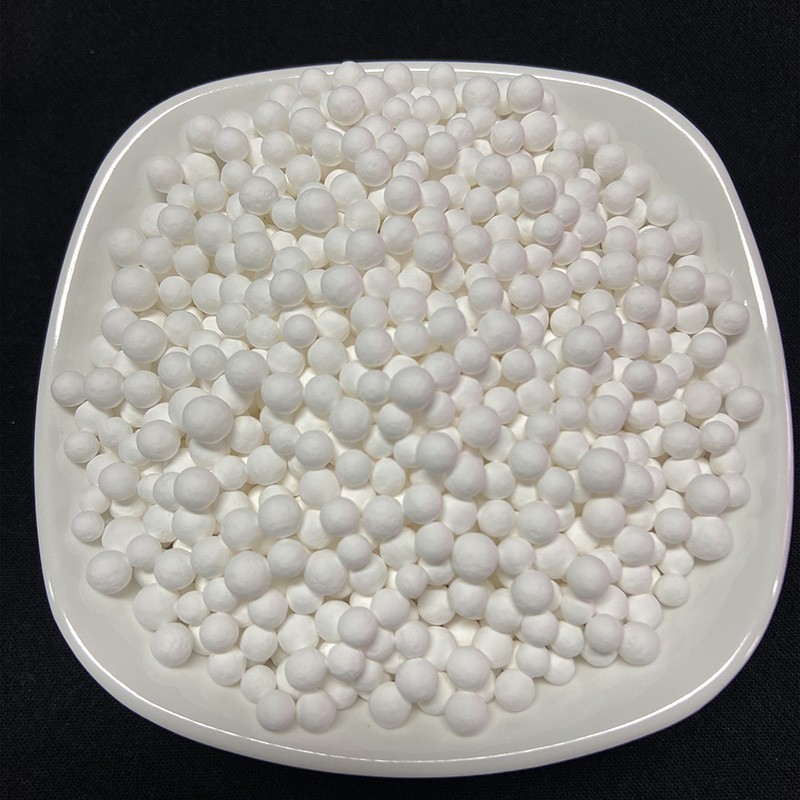

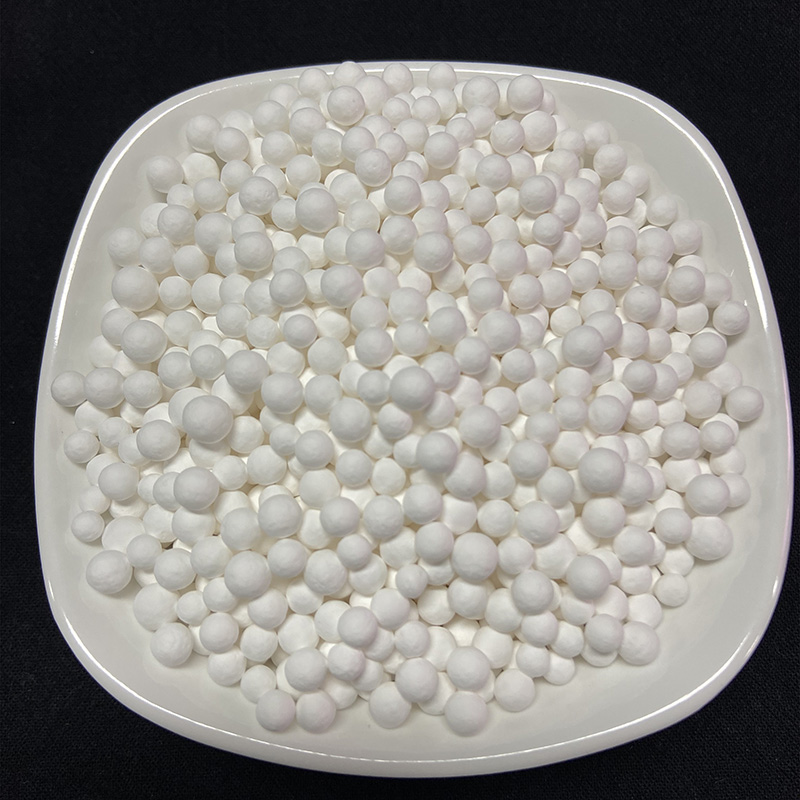

Globus Ceramicus Aluminae Inertis Altae Aluminae / Globus Ceramicus Aluminae 99%

Proprietates Physicae et Chemicae Globorum Ceramicorum Inertium

| Proprietates physicae et chemicae globulorum ceramicorum inertium | |||||||

| Elementum | Al2O3¼� | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3¼� | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Ceterae partes per negotiationem inter venditorem et emptorem, si opus sit, determinari possunt. | |||||||

| absorptio aquae, % | 3±1, etiam per negotiationem inter venditorem et emptorem determinari potest. | ||||||

| proportio, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Densitas massae, kg/m³ | 1400-1550 | 1400-1650 | MD-MDCCC | 1700-1950 | MDCCC-MCML | ≥1900 | |

| Pulvis, fissura vel frangitio | Saccus singularis minus quam 5% est. | ||||||

| Deviatio magnitudinis | Sphaera uniformis, proportio diametri maximi ad minimum sphaerae ceramicae non excedit 1.2 | ||||||

| Tolerantia dimensionalis | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26—50mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Robur casus liberi | Ratio sine damno ≥99% | ||||||

| Robur compressivum | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | LX-LXXX | ≥80 | ≥82 | ≥85 | ||

| Ratio detritionis % | ≤2 | ≤1 | |||||

| solubilitas acidi, 3 | ≤6 | ||||||

| Alcalinitas, 3 | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractarietas, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Resistens subitae differentiae pressionis | Ratio non destructiva ≥ 99%, nulla mutatio in robore compressivo et pressio post mutationem subitam minus quam 25% est. | ||||||

| Resistens repentinis mutationibus temperaturae | Ratio sine damno ≥99% | ||||||

| Sarcina | Involucrum tympani ferrei | In tympanis ferreis conditum, saccis crassis PP vel PE plasticis obsignatum | |||||

| Involucrum sacculi texti | Praesto in saccis textis firmis et radiis ultraviolaceae resistentibus | ||||||

| Nota: Data densitatis massae ad referentiam tantum sunt, non ut basis acceptationis. | |||||||

Alia Nota: Vide Tabulam 5 Pro Absorptione Aquae Globorum Implentium 99

| 99 Globus Implens Absorptio Aquae | ||

| impletio 99 | diameter | diameter |

| formatio volubilis | φ <25mm | <5% |

| Machina preli formans | φ > 25mm | <10% |

Indicatores Technici 99.5%

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| CaO +MgO | ≤0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Index Physicus Globi Impletorii Chemici

| CONDITIO | INDEX |

| Mollitio oneris (yb/t370-1995) | Deformatio sub pressione 0.2mpa minor est quam 0.6% |

| Resistentia impetui thermali (yb/t376.2-1995) | 1200°C usque ad 600°C. Decies sine fissuris superficialibus. |

| Mutationes lineae recombustionis (gb/t3997.1-1998) | 1400 ℃ per 12 horas, valor maximus est 0.25%, valor medius est minus quam 0.20% |

| Densitas massae (gb/t2997-2000) | 3.2-3.50 g/cm³3 |

| vis opprimens | Plus quam 230 kg/cm2 occurrere |

| Porositas apparens | 12-18% |

| Densitas massae | 2.1-2.3g/cm³3 |

Impletio Chemica Globulorum Impletio

1) Involucrum ordinarium: saccus polyethyleni textus cum pondere netto 25kg, plus pallet

2) Involucrum tympanorum ferreorum: involucrum tympanorum ferreorum 100L, palletae addi possunt